Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

biogas power generation

Jianan Wang

Contact person

Basic Information

| Brand Name | PUXIN |

|---|---|

| Place of Origin | Guangdong China (Mainland) |

| Application | Cooking Fuel |

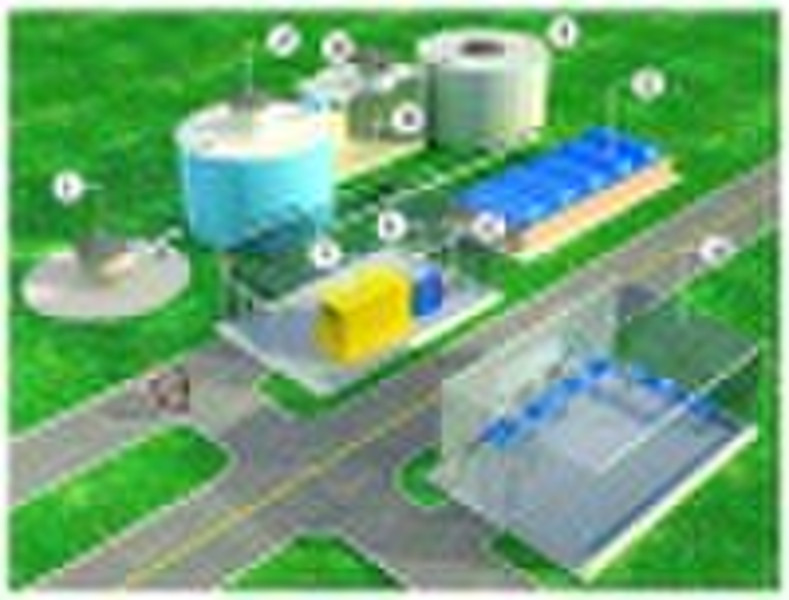

1.Introduction PUXIN Household biogas digester system for waste treatmentis composed of a 6 or 10 m3 PUXIN biogas plant, pipe routes, gas purify devices and gas appliances or small power biogas generator. PUXIN Household biogas digester system for waste treatmentismainly applied to farmhouse or domestic house to treat livestock waste, straw, human sewage and food waste. 2. Contrast between fixed dome and Puxin biogas plant Contrast of the technical requirements for the builders Items The traditional fixed dome hydraulic biogas plantThe Puxin Biogas plantAirtight craftHighly requiredNot requiredAbility to understand blueprintHighly requiredNot requiredAbility to build the archHighly required (build by hand)Not required (cast by mould)To judge and deal with gas leakingHighly requiredRequiredTo judge and deal with water leakingHighly requiredRequiredTraining periodAbout 3 monthAbout one weekPeriod to become a proficient builder1-2 yearsAbout one monthRequirement of the people to be trainedMedium educated, strong ability to master skillsNot Educated, medium ability to master skillsSuccess rateNot 100% guaranteed100% guaranteed Contrast of the maintenanceItemsThe traditional fixed dome hydraulic biogas plantThe Puxin Biogas plantTo mend the gas leak of gas-holder Dangerous and difficultThe job is done inside the biogas digester, there is a possibility of poisoning.The leak can not be found.Safe and easyThe job is done on ground, there is no possibility of poisoning. The leak can be seen, and can be mended directly.To mend the water leak of the digesterDangerousThe digester’ outlet is too small that the air circulation in the digester is bad. So, there is a possibility of poisoning.SafeThe digester’s outlet is large enough that the air circulation in the digester is good. So, there is no possibility of poisoning. 3. Construction process 4. Cost breakdown of 10 m3 Material (manpower) quantity Glass fibre reinforced plastic Gasholder 1 Smashed stone 4m3 Sand 3.5m3 cement 1400kg Brick(60×120×240mm) 100 Plastic pipe (Φ150×1800mm) 2 concrete bar (Φ6) 8kg manpower 6 man×1 day (digging a hole)+ 6 man×1 day (casting concrete)+ 2 man×1 day (to build inlet, outlet and install pipe systems) Earth work 40 m3 (steel mould with outer)

Delivery terms and packaging

Port: Shenzhen

Payment term

Letter of credit

Telegraphic transfer

MoneyGram

Western Union

-

Payment Methods

We accept: